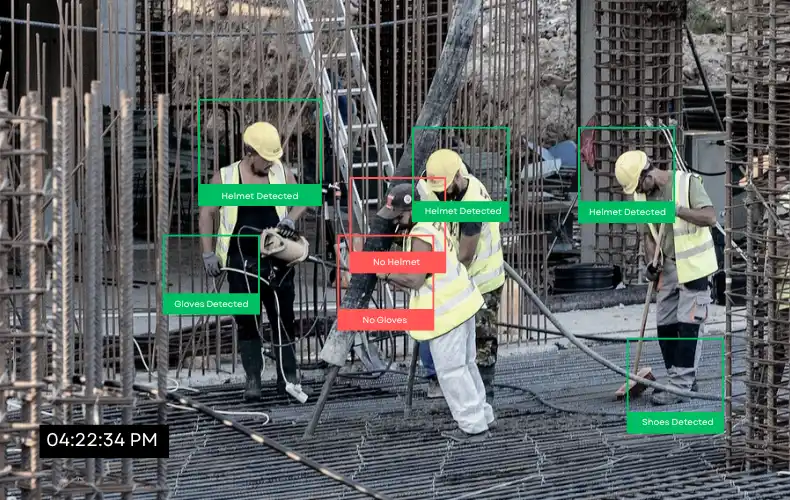

Automated Safety Gear Identification

The client needed an AI solution that was non-invasive and could detect the presence of a helmet, gloves, and reflective vest automatically and without human intervention, maintaining a steady level of conformity to regulatory and internal safety requirements.

Instant Violation Alerting

They required a real-time alert system to inform supervisors every time that safety regulations were violated. This feature was supposed to decrease response time and avoid incidents before escalation.

Low-Latency Edge-Based Deployment

It needed a processing system that could be used in low-connectivity settings in a reliable way. Edge inference had to be implemented to provide continuous detection and rapid response in critical situations.

Supervisors struggled to have a consistent presence in various zones; thus, the quality of monitoring was inconsistent, particularly when there was a lot of activity or when shifts were long.

There was an inconsistency in safety compliance between day and night shifts, which produced inconsistent risks. A standardized compliance expectation required a consistent and automated observation mechanism.

The unstable connectivity in parts also influenced cloud-only monitoring methods, which

led to slow processing speeds and delayed alert generation.

Some production areas had heavy machinery and a high rate of worker movement, and it was difficult to confirm gear use or a close working environment as a sole action because it was difficult to see and assess it manually.

Lightweight Vision Model Optimization and Deployment

An optimized YOLO-based detection model was tested and implemented on NVIDIA Jetson Nano, allowing real-time inference on edge devices. A Python-OpenCV stack was used to process frames and ensure precision and speed in dynamic factory environments.

Real-Time Automated Alert Engine

An automated alert engine that runs on the principle of rules was introduced to provide immediate alerts when the absence of safety equipment or unsafe activities among workers is detected. Model outputs detected alerts automatically, and they were sent via the established supervisory channels of the client.

Hazard Zone Proximity Detection

To monitor distances of workers to dangerous machinery zones, a special spatial-analysis component was created. Unsafe proximity detection and imminent warnings were achieved by using bounding-box geometry and distance estimation with vectors.

Compliance Reporting and Insight Dashboard

To consolidate violation logs, show shift-specific analytics, and create compliance heatmaps, a centralized dashboard was provided. Measured local inferences were periodically reported, and long-term safety was appraised to the cloud.

The client is a developing European industrial manufacturer with several fabrication plants and large-volume production floors. Its activities entail the machineries, heavy equipment, and multi-shift manpower management, which pose a high demand to sustain the safety checks and sound compliance procedures. As the organization grew production goals and safety requirements, it needed a sophisticated and reliable system that would enhance on-ground visibility and decrease the number of manual supervisors in the busy areas of operation.

The AI safety solution enhanced our monitoring procedures and made compliance visibility much more visible. Melonleaf’s team was very attentive to all required changes and available at all times.

The AI Safety Monitoring solution offered the client a shift in the effectiveness of safety compliance management within the manufacturing environment. The system, using edge-based inference, did not require network stability and was capable of detecting gear usage and on-site proximity dangers fast.

This implementation demonstrated that an intelligent vision system can be deeply incorporated into the industrial processes to protect workers and increase resilience to operational challenges. A scalable and future-ready safety infrastructure was created by integrating lightweight AI models, efficient processing pipelines, and structured reporting, which could serve the continued growth and changing safety needs.

Get in touch to discover tailored strategies that move your business forward.

Get in touch with our certified consultants and experts to explore innovative solutions and services. We’ve empowered companies across various domains to transform their business capabilities and achieve their strategic goals.